Passavant has always been a name synonymous with the excellence of execution through innovation. Established in 1842 in Germany, Passavant Energy & Environment (formerly Passavant-Roediger) developed groundbreaking technologies and processes in municipal wastewater, sludge, water and industrial wastewater treatment, including the company’s in-house world-renowned sludge digestion technology. A Lamella separator technology a state-of-the-art four-stage process used for water treatment.

Today, Passavant Energy & Environment’s (PE&E) steady growth and the establishment of various subsidiaries in Europe, MENA and Asia open a gate to establish and acquire businesses in new markets. Winning awards for projects worldwide, including, but not limited to North Africa, UAE, Saudi Arabia, Iraq, Lebanon, Turkey, Europe and Asia, including China and Vietnam.

Always visualizing, the company strived from its roots in environmental preservation further to encompass Energy Re-Use, in addition to Water Re-Use; thereby dually focusing on both of the globally limited resources simultaneously. PE&E’s portfolio includes more than only Green Energy solutions but elevating its project delivery from full turnkey EPC contracts to holistic solutions for Water and Energy Re-Use. Passavant Energy & Environment’s paradigm shift in solution provision is well-defined as a comprehensive benefit: PE&E is a complete solution provider and encompasses EPC contracting, Operation&Maintenance service provision, financing, as required by the client but under the umbrella of a complete water and energy resource optimization scheme.

PE&E is 100% owned and the subsidiary of Drake&Scull International PJSC.

Services List

Due to our long-term experience in municipal Wastewater Treatment, we develop unique process concepts adapted to the plant – from inlet to outlet. PASSAVANT Energy & Environment offers state-of-the-art Wastewater Treatment technologies, Sludge Treatment as well as customized process technologies for every step of the process.

Profiting from the most innovative developments in technology we uplift our portfolio from consultancy, design, supply of equipment over installation, commissioning, Operation & Maintenance up to the construction of complete turnkey Wastewater Treatment Plants to holistic solutions with Energy Re-Use features to the benefit of our customers.

Our specialized Turbo-LME process which has been optimized over decades offers optimal clear water quality and optimally combines the stages of flocculation/precipitation and sedimentation in the lamella separators, incl. the thickening stage of the created sludge.

Benefits:

- Eco-friendly and cost-efficient Energy Re-Use

- PASSAVANT Energy & Environment guarantees the production of electricity with the highest efficiency among peers in the industry

- International experience and employment of local workers managed by our professionals to deliver German standard

- Conversion of heat into energy

For concepts of water supply, we give priority to sustainable Energy Re-Use and recycling regarding industrial consumption. For the supply of drinking water, we develop centralized as well as de-centralized treatment concepts, with the overall aim to maintain a secure supply, regardless of the variety of available raw water sources.

Equal whether the available raw water resources are:

- Surface water with a strong human impact and natural influences,

- Ground- or spring water with a geogenic character and maybe agricultural influences or

- Seawater

we will consider your overall treatment objective with all its requirements. This analysis will lead to specific treatment solutions guaranteeing a steady state drinking-water of the required quality and ensuring a continuous supply.

Benefits:

- Tailor-made solutions for individual demands regarding the environment or infrastructure, i.e., water shortage

- Potable water in highest standards

- Project refurbishment under full operation

Being a holistic solutions provider serving the international market, Passavant Energy & Environment has gained experience with different cultural and environmental demands and refined its sense for the requirements of tailor-made projects for clients.

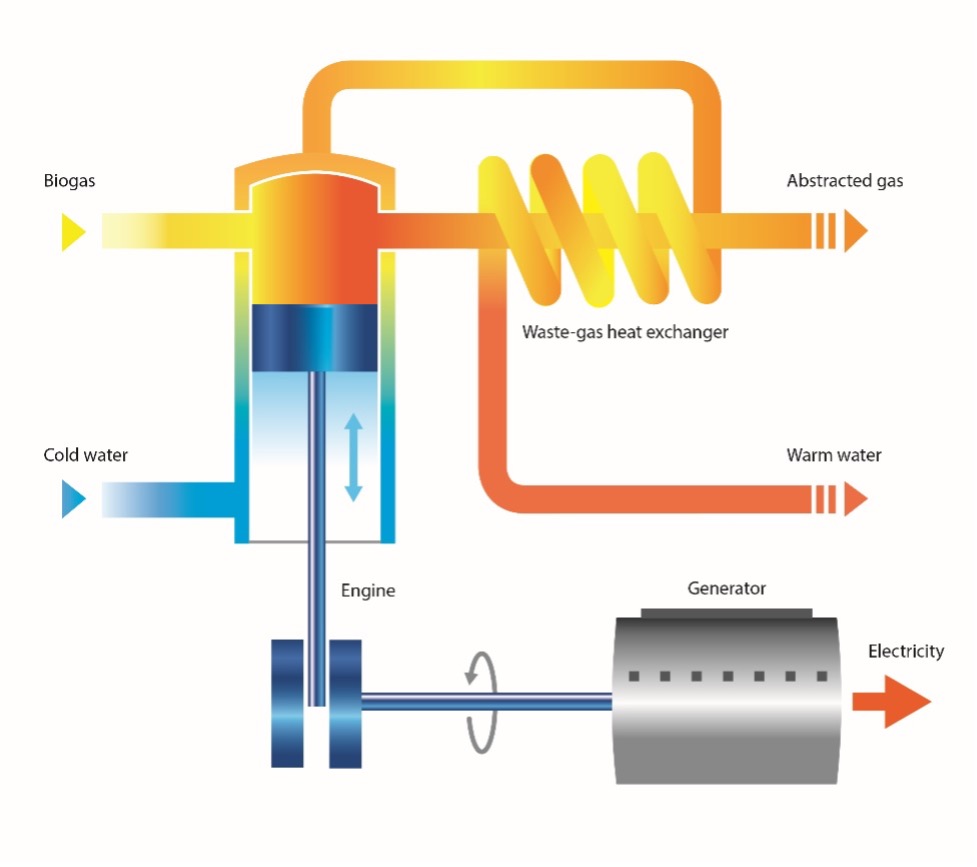

In the field of Wastewater Treatment, Sludge Treatment and Waste Treatment, Passavant Energy & Environment can extract the most from biogas to the benefit of the client. Renewable Energy is not new to the industry; moreover, it is a must for an innovative, forward-thinking business. What PASSAVANT ENERGY & ENVIRONMENT offers the client is the maximization of the green energy generation and re-use from the biogas produced due to the configuration of our system: PASSAVANT ENERGY & ENVIRONMENT’s Energy Re-Use concept gives the client the most suitable technology plus an add-on that guarantees the production of electricity with the highest efficiency among peers in the industry. Furthermore, we know how to use CHP in many more ways other than with biogas.

Benefits:

- Enhanced CHP: PASSAVANT ENERGY & ENVIRONMENT guarantees the production of electricity with the highest efficiency among peers in the industry

- Plant energy demand can be covered, and surplus electricity can be supplied to the national grid

- No external heat supply needed

- Protection of natural resources by utilization of the produced biogas

- Reduction of CO2 emissions

- Production of valuable, homogenous, nutrient-rich fertilizer

- Reduction of waste to landfill

- Rendering of Waste as harmless; up to Class A. The economic and ecologic rationale behind the heat-operated plant (the CHP’s output follows the demand for heat) is to use all the heat that has been generated on the spot. Surplus electricity can be supplied to the national grid. Therefore, less generator or external capacity is needed, substitutes the increasing usage of CHP the electricity from fossil condensing power plants of medium load (mainly coal) and thus enables a lower carbon dioxide emission.

Aspect on Ecology and the Environment

As mentioned above, CHP reaches an overall significantly higher utilization rate compared to the conventional power plant on a coal base, where half of the energy produced is obtained as waste heat. Using it as community heating would mean significant transport losses (10 – 15%) and require a complex and expensive pipeline network, as by central power plants the heat source and heat consumer usually far apart. Moreover, about 2 to 5% of the energy gets lost when electricity is transported via a pipe. Common CHP has an electrical efficiency of approximately 25 to 38 % (depending on the size and type), whereas Passavant Energy & Environments guarantees the production of even more electricity. The overall efficiency of about 90% can only be achieved when electricity and heat can be used directly on site.

Picture 1: Basic CHP scheme

PASSAVANT Energy & Environment offers a wide range of standard design package system for a lot of different applications, such as for water or sewage treatment (including tertiary quality) or reverse osmosis plants. Advantages of a package system are the quick deployment, remote area operation and of course the proven technology and performance. Relocation of a package system is always possible if required. The full automation provides for an easy operation.

Benefits:

- fast delivery time (potentially on site in 6-12 weeks)

- modular

- minimum start-up and commissioning times

- ease of relocation as and when required

- fully automated operation

Tailor-made solutions and supply of spare parts or consulting on individual requests are developed and handled by our experienced team in close coordination with the client or plant operator. We implement Energy Re-Use by default within our Operation & Maintenance philosophy and this translates into minimized demand on consumables of electricity and maximized enhanced energy recovery from operation by focusing on the core: the process.

Benefits:

- Plant performance assessment and performance improvement

- Add on features, tailor-made extensions

- Multiple locations worldwide ensure on time response

- Equipment replacement, spare parts supply, and installation

- Diagnostics

- Reduction of energy usage, chemical usage, and waste production

- Reduction of downtime

- Achievement of the highest quality product

- Control Software optimization

- Service visits (repairs and refurbishment)

- Training

- Trouble shooting

Fast and efficient After Sales Service is the key to smooth and successful treatment plant operation and performance.

To maintain our client’s confidence, we offer Enhanced After Sales Services, differentiating us from standard after sales service and thus strengthening our competitiveness. For our clients, this means having the benefit of implementing advanced, cost-effective strategies and processes to increase the plant’s performance and reduce usage of consumables.

Benefits:

- Operation and Maintenance for any type of plants and equipment

- long term or either short term Operation

- Plant performance assessment

- Process and plant optimization

- Professional Training

- Remote monitoring

The core principle of Passavant Energy & Environment is to maintain world-class service with German standards. The fully integrated Management System certified to DIN EN ISO 9001, 14001 and 45001 ensures that the relevant requirements for quality are recognized for all projects until the completion of work in terms of Planning, Manufacture, Delivery and Operation of products and plants for waste water purification, treatment of potable water and municipal solid waste and refurbishment of hydro power plants.

All our activities are performed in a planned and systematic manner under procedural control to ensure that all projects are progressively controlled / assured until completion of the work.

All personnel working within the Company are responsible for the quality of their work and perform their duties in accordance with the requirements of the manual and the referenced procedures.